LV MOTOR ANALYSIS IN KENYA

24 Apr, 2023 3:06 PM

For expert LOW VOLTAGE (LV) ANALYSIS Solutions, get in touch with Sprintex Engineering Services - the leading Electric Motor Rewinding and Electrical Motor Rebuilding Services Provider in Kenya.

What are electric motor rewinding and electric motor rebuilding services and why do you need them? Rewinding is the process used as a way to repair shorted, grounded or damaged motor coils. We perform motor analysis by inspecting if the DC Motor Rewinding for your motor is properly done. If not do return the rewound coil and reinstall it with rebuilt armatures or other components as needed to get your motor back functioning properly again.

Our Motor Rewinding Analysis Process

It takes us numerous stages to professionally analyze electric motor rewinding services:

Record Pertinent Data:

We start by recording all the necessary data that is needed to rewind the motor, including the number of slots, number of coil turns, pitch and necessary wire size for making coils to rewind the motor.

Remove Faulty Windings:

The problematic windings are removed once the records of all of the relevant information are entered it into our database. We then clean the motor of any remaining varnish, insulation, or impurities before rewinding it, using media blaster to effectively remove trash and particles without hurting the motor.

Steam Clean the Stator and Paint With Insulation Paint:

We then perform Steam cleaning the stator and all the other parts of the motor to make sure they are free of contaminants. Once it is all clean, we paint inside the stator with insulation paint. We then install liner insulation in the stator slots so that the coils do not make contact with the core.

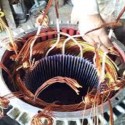

Create new coils and place them in the stator slots:

At this stage, we make fresh coils. The motor’s type will then determine the sort of winding head we use to wind the motor. After the coils have been made, proper and efficient placement in the corresponding stator slots follows. We apply wedging once the coils are in place to insulate and preserve the coil.

Lace it up:

The next phase involves adding lacing for more support. Finally, new motor leads are connected and a complete quality test is performed. We then perform a dielectric test to verify the integrity and quality of the winding.

Cure the motor and put it to the test:

We then finally cure the motor and retest it to ensure that it is operating ideally and optimally as planned. While this may appear to be a time-consuming and difficult operation, it is nearly automatic by Sprintex Engineering Services Ltd Motor Repair Professionals.

Our Motor Wellness Specialists have winded hundreds of thousands of motors and are well-versed in the procedure. When you call or visit us for LV Motor Analysis, Rewind and Repair Services, you can be certain that you will receive a high-quality motor that performs almost as well as new at the conclusion of the process.

Serving you is our pleasure. You will not go wrong by choosing us to perform your Motor Analysis, Rewind, Repair and Maintenance; at the best price you can find around.

LV Motor Repair LV Motor Analysis Motor Rewinders in Kenya Electrical Motor Rebuild DC Motor Rewinding Armature Rebuild Electric Motor Rewind Specialists in Kenya Sprintex Engineering Services Ltd Kenya