Sprintex Engineering Services Ltd

Komarock Road, Mowlem Area, Off Kangundo Road, Nairobi

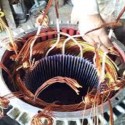

Sprintex Engineering Services Ltd is an electrical engineering company in Nairobi, Kenya specializing in comprehensive electric motor rewinding, transformer rewinding, alternator rewinding, transformer refurbishment, electric motor refurbishment, transformer repair, welding machines repair, complete motor mechanical repairs, general electrical repair services, synchronous motors and electric generator repairs.

We professionally strive to offer quality based international standards electrical services by only using SKF rolling bearings on all repaired rotating electrical machines and impact tools to fit the bearings. We rewind all electrical equipment to class H insulation system.

We do itemised quotations to our customers that are accompanied by photos showing the failures and a comprehensive technical analysis detailing the cause of motor failure and corrective measures to prevent future re-occurrence. We subject all repaired electric machines through instrument and electrical tests before dispatch, as per international standards and quality test report provided on request.

The insulation materials, cable and parts we deal in include;

• Thermistors

• Imported Winding Copper Wires

• Insulation Paper

• Terminal Blocks

• Bearings

• Sleeves, Flexible Cables and Cooling Fans

• Epoxy Resin and Hardener

• Silicon Cable

• Centrifugal Switches

• Rotary Switches

• Quality Fans

• New Slipping

• Carbon Brushes

• Capacitors

• Cables

• Mica & Glass Tapes

• Lugs

• Cable Sleeves

• Binding Tape

• Brush Holders & Carbon Brushes

The tools we use include

• Testing Equipment

• Multimeter

• Laser Temp Gun

• Ac/Dc Clamp Meter

• Insulation Tester

• Skf Tachometer

• Multimeter

• Insulation Tester

• Infrared Thermometer

• Rpm Meter

• Milliohm Meter

All our rewinds of electric machines are guaranteed for a period of one year from date of invoice and dispatch subject to the machine being operated within acceptable and allowable motor/generator specifications. The guarantee does not however cover failures attributed to mishandling, overload, phase failure, voltage surges, contaminants and mechanical failures. We promise and deliver quality based electrical services at affordable rates to our customers. We work on weekends on prior arrangement and offer transport within Nairobi County & its environs including Thika town, at no extra charges.

0721 692342

0735 944253

0724 125211

Garage and Welding Equipment Repair in Kenya

We are the leading Garage Equipment and Welding Equipment Specialists in Nairobi, Kenya. We specialize in repair and service of welding equipment: including Gas Cutting Apparatus, Cutting Torches, Regulators, Flow Meters, Electric Welders, Engine-Driven Welders and Plasma-Cutting Machines, among many more. Our range of garage equipment & welding machine solutions targets Tig Welding Machines, Arc Welding Machines, Safety Gear & Equipment, Gas Welding Machines, Mig Welding Machines, and Plasma Welding Machines.

When we receive your machine, we diagnose the problem as soon as possible, by offering workshop demonstrations for you to experience top-end garage and welding machine and to assist you make an informed buying decision and provide you with a detailed estimate for the necessary repairs, when replacing your older equipment. We also provide breakdown service for emergency repairs and are equipped for mobile repairs as well.

Our Garage Equipment and Welding Equipment Repair Services include:

• On-site/field diagnostics

• Welder/equipment pickup and delivery

• Breakdown service for emergencies

• Fast turnaround

• Warranty repairs

• Calibration

Our workshop and repairs centre boasts state of the art facility – staffed by experienced technicians with extensive experience in the repair and operation of all welding equipment, electric motors to class H insulation system, bar winding of all types of slip ring and DC motors, carry out comprehensive electrical and mechanical diagnostics. We only use SKF rolling bearings for all repaired rotating electric machines and we carry out comprehensive mechanical repairs of electrical motors and generators to their original manufacturer’s specification.

Why our customers trust us:

• Minimal downtimes due to repairs

• Quick and dedicated support from our welding repairs experts

• On-site customer training provided

• Regular maintenance and service plans

• Professional, high-quality repairs using original spare and wearing parts

• Calibration and certification

Just give us a call and we shall be at your service with quality and service offered at the right price.

Contact us on 0721 692342, 0735 944253 or visit us along Komarock Road, Mowlem Area, Off Kangundo Road.

Garage and Welding Equipment Repair Gas Cutting Apparatus Cutting Torches Regulators Flow Meters Electric Welders Engine-Driven Welders and Plasma-Cutting Machines Tig Welding Machines Arc Welding Machines Safety Gear & Equipment Gas Welding Machines Mig Welding Machines

Read MoreLV MOTOR ANALYSIS IN KENYA

For expert LOW VOLTAGE (LV) ANALYSIS Solutions, get in touch with Sprintex Engineering Services - the leading Electric Motor Rewinding and Electrical Motor Rebuilding Services Provider in Kenya.

What are electric motor rewinding and electric motor rebuilding services and why do you need them? Rewinding is the process used as a way to repair shorted, grounded or damaged motor coils. We perform motor analysis by inspecting if the DC Motor Rewinding for your motor is properly done. If not do return the rewound coil and reinstall it with rebuilt armatures or other components as needed to get your motor back functioning properly again.

Our Motor Rewinding Analysis Process

It takes us numerous stages to professionally analyze electric motor rewinding services:

Record Pertinent Data:

We start by recording all the necessary data that is needed to rewind the motor, including the number of slots, number of coil turns, pitch and necessary wire size for making coils to rewind the motor.

Remove Faulty Windings:

The problematic windings are removed once the records of all of the relevant information are entered it into our database. We then clean the motor of any remaining varnish, insulation, or impurities before rewinding it, using media blaster to effectively remove trash and particles without hurting the motor.

Steam Clean the Stator and Paint With Insulation Paint:

We then perform Steam cleaning the stator and all the other parts of the motor to make sure they are free of contaminants. Once it is all clean, we paint inside the stator with insulation paint. We then install liner insulation in the stator slots so that the coils do not make contact with the core.

Create new coils and place them in the stator slots:

At this stage, we make fresh coils. The motor’s type will then determine the sort of winding head we use to wind the motor. After the coils have been made, proper and efficient placement in the corresponding stator slots follows. We apply wedging once the coils are in place to insulate and preserve the coil.

Lace it up:

The next phase involves adding lacing for more support. Finally, new motor leads are connected and a complete quality test is performed. We then perform a dielectric test to verify the integrity and quality of the winding.

Cure the motor and put it to the test:

We then finally cure the motor and retest it to ensure that it is operating ideally and optimally as planned. While this may appear to be a time-consuming and difficult operation, it is nearly automatic by Sprintex Engineering Services Ltd Motor Repair Professionals.

Our Motor Wellness Specialists have winded hundreds of thousands of motors and are well-versed in the procedure. When you call or visit us for LV Motor Analysis, Rewind and Repair Services, you can be certain that you will receive a high-quality motor that performs almost as well as new at the conclusion of the process.

Serving you is our pleasure. You will not go wrong by choosing us to perform your Motor Analysis, Rewind, Repair and Maintenance; at the best price you can find around.

LV Motor Repair LV Motor Analysis Motor Rewinders in Kenya Electrical Motor Rebuild DC Motor Rewinding Armature Rebuild Electric Motor Rewind Specialists in Kenya Sprintex Engineering Services Ltd Kenya

Read MoreHV SWITCHGEAR REPAIR IN KENYA

We are experts in HV SWITCHGEAR REPAIR and MAINTENANCE IN KENYA. We have hands-on experience around the Repair, Installation and Maintenance of new and used HV Switchgears 3.3kV to 33kV, Vacuum or SF6 interrupters, fixed pattern or with- draw-able, air-insulated or gas-insulated switchgears. We are equally familiar with LV 415V switchgears.

At Sprintex Engineering Services Ltd we carry out the latest test equipment for all repair test services offered, whether it is a speed trace test, a protection test or a high voltage pressure test that needs to be done we have the tester.

The Medium and High Voltage Equipment Repair Services we offer include:

Medium voltage switchgear up to 33kv including:

• Air-Insulated Switchgear (AIS)

• Air Blast Switchgear (AIS)

• Low And High-Volume Oil Circuit Breakers (OCB)

• Sulfur Hexafluoride Circuit Breakers (SF6)

• Vacuum Circuit Breakers, Vacuum Interrupter (VCB)

• Medium Voltage Contactors

Protection and Regasing of High voltage circuit breakers up to 132kv on

General Panel Repair & Maintenance

• Cleaning and Lubricating of Cradle Mechanisms

• Connection Inspections and Testing

• Pressure Testing

• General Cleaning

We also offer Low Voltage Equipment Repair Services, including:

Compact and Air Circuit Breakers

• Old and current technology

• Up to 6300 amps

• Alternating and direct current

• Fixed & with-draw-able

• Nuclear rated

Protection

• Mechanical

• Electromechanical

• Electronic

Change Over Systems

Power Factor

General Panel Maintenance

• Cleaning

• Connection inspections

Preventative Maintenance

• Infra-red inspections

• Partial discharge testing

Substation Routine Inspections

• Battery checks

• Visual inspections

Avoid nasty cost shocks and unplanned downtime. Our service reps are ready to advise you on the best service plan for your facility. We will also help you choose the repair and maintenance plan that suits your business.

Our Contacts:

Springtex Engineering Services Ltd

Mobile: 0721 692342, 0735 944253 or 0724 125211

Along Komarock Road, Mowlem Area, Off Kangundo Road, Nairobi

Email: [email protected]

HV Switchgear Repair SF6 Interrupters Fixed Pattern With-draw-able Switchgears Air-Insulated Switchgears Gas-Insulated Switchgears High Voltage Equipment Repair Air-Insulated Switchgear Air Blast Switchgear Low and High-Volume Oil Circuit Breakers Sulfur Hexafluoride Circuit Breakers (SF6) Vacuum Circuit Breakers Vacuum Interrupter Medium Voltage Contactors Switchgear Maintenance Sprintex Engineering Services Ltd Kenya

Read MoreTraction Motor Repair in Kenya

Sprintex Engineering Services Ltd are specialists in Rewinding of Rotating Machines, Transformers and Generators in Kenya. We have been extensively involved in the Traction Motor repair and rewound for 5M2A Traction Motor, 6E1 Traction Motor and 8M Traction Motor for many years. We are a leader in rewinding techniques and technology to improve the functionality and performance of electric motors.

Traction and Auxiliary Armatures

At Sprintex Engineering Services Ltd, Traction and Auxiliary Armatures can be completely reproduced or repaired. We are one of the leading Motor Repair and Refurbishment solution providers, with extensive technical knowhow on rotating machines in Nairobi, Kenya.

We offer the following Traction Services

5M2A Traction Motor Products:

Frame, Endshield Pinion End, Endshield Commutator End, Shaft, Labyrinth Seal Sleeve Pinion Inner, Nut Plain Round, Plate Retaining Bearing, Washer Cap, Labyrinth Seel Sleeve Commutator End, Labyrinth Seal Sleeve Pinion End, Seal Ring Metal, Labyrinth Seal Sleeve Groove Commutator Inner Bearing Cap, Inner Bearing Cap, Deflector Dirt & Liquid Ring, Plate Retaining Bearing, Disk Locking Plate, Cover Linage, Pinion Key, Commutator Cover, Cable Bracket, Cable Cleat and Plate, IP Coil Edge Wound, Field / Shunt Coil, Armature Coil, Armature Rewind and Traction Motor Complete

6E1 Traction Motor Products:

Air Duct, Endshield Pinion End, Endshield Commutator End, Shaft, Labyrinth Seal Sleeve Pinion Inner Bearing Cap, Nut Plain Round, Plate Retaining Bearing, Washer Cap, Labyrinth Seel Sleeve Commutator End, Labyrinth Seal Sleeve Pinion End, Seal Ring Metal, Labyrinth Seal Sleeve Groove Commutator Inner Bearing Cap, Deflector Dirt & Liquid Ring, Plate Retaining Bearing, Disk Locking Commutator End, Bearing Lock Plate, Pinion Key, Commutator Cover, Cable Cleat and Plate, IP Coil Edge Wound, Field/Shunt Coil, Armature Coil, Armature Rewind and Traction Motor Complete

8M Traction Products:

Endshield Pinion End, Armature Rewind, Shaft, Labyrinth Seal Sleeve Pinion Inner Bearing Cap, Nut Plain Round, Plate Retaining Bearing, Washer Cap, Spacer Seal Pinion End, Labyrinth Seal Sleeve Commutator End, Labyrinth Seal Sleeve Pinion End, Labyrinth Seal Sleeve Groove Commutator Inner Bearing Cap, Disk Locking Commutator End, Bearing Lock Plate, Commutator Cover, IP Coil Edge Wound, Field / Shunt Coil and Armature Coil

We provide traction motor services including;

• Reshaft of Armatures

• Commutator Fitment and Repairs

• New Commutator Titment

• Rewinding of Traction and Auxiliary Armatures

• Complete Rebuild of Traction and Auxiliary Armatures

• Commutator Turning to High Precision

• In house Coil Manufacturing

Our staff members have many years’ of extensive knowledge on insulation applications and always assist to design insulation systems within the Traction Sector. We are experienced within the Traction environment and offer consulting Services as and when required from our Customers

Our Contacts:

Springtex Engineering Services Ltd

Mobile: 0721 692342, 0735 944253 or 0724 125211

Along Komarock Road, Mowlem Area, Off Kangundo Road, Nairobi

Email: [email protected]

Traction Motor Repair M2A Traction Motor 6E1 Traction Motor 8M Traction Motor Electrical Rewinders Motor Repairs Auxiliary Armatures Traction Armatures Reshaft of Armatures Commutator Fitment and Repairs Commutator Turning to High Precision Sprintex Engineering Services Ltd Kenya Nairobi Rewinding on Rotating Machines

Read MoreCarbon Brushes in Kenya

At Sprintex Engineering Services Ltd we manufacture high quality CARBON BRUSHES of any grade or blade to suit application electric motors, alternators and electric generators to conduct current between stationary wires and moving parts. Our Motor Carbon Brushes are designed and manufactured in adherence with international quality standards, to meet the varied demands and application needs of our clients.

We offer Carbon Brushes with several technical specifications at cost effective rates and suitable for the following application:

• Slip-Ring Induction Motors

• Variable Speed AC Motors

• DC and Traction Motors

• Brush-type Alternator

• Vacuum Pumps

Our Carbon Motor Brush Features include:

• Optimum performance

• Maintenance free

• High conductivity

• Enhanced service life

• Rugged construction

• Precise dimensions

• Anti corrosive

We also supply Carbon Brush Holders, Tensioning Springs and Associated Parts.

We are a household name in Rewinding and Repair of All Electric Motors, Transformers, Alternators, Pumps and Refrigeration Compressor in Nairobi. We are specialists in Vibration Analysis, Condition Monitoring, Fault Finding, Commutation Checks and Repairs, On-Site Balancing, Surge Testing, Computerised Winding Data Programs, and In-House Machining too.

Our Contacts:

Springtex Engineering Services Ltd

Mobile: 0721 692342, 0735 944253 or 0724 125211

Along Komarock Road, Mowlem Area, Off Kangundo Road, Nairobi

Email: [email protected]

Carbon Brush Motor Brush Tensioning Springs Carbon Material Vacuum Pumps Slip Ring Induction Motors Variable Speed AC Motors Carbon Brush For Electric Motor Kenya Nairobi Carbon Motor Brushes in Nairobi Grinder Carbon Brushes Motor Carbon Brush Manufacturers in Kenya Carbon Products

Read MoreMegger Resistance Testing in Kenya

Sprintex Engineering Services Ltd are provider of MEGGER RESISTANCE and HV (High Voltage) TESTS services in Kenya. We are experts in testing circuits for the existing connections or melted fault areas that may have occurred during a fire event. We then analyze the results, isolate and replace the specific circuits in case of a fire talk to your adjuster to ensure that there are no further problems on your affected circuits.

Benefits of Megger Testing

Proactive Equipment Condition Analysis

Reduced Risk of Emergency Power System Failure

Predictive Repairs

Asset Management

Predictive Equipment Life Expectancy

We have the equipment on hand and the expertise to perform your Megger Testing and get those results for corrective measures to be taken. We are here to help you make sure your existing wiring is safe, and of course, to install new wiring as needed as well. We are here for all of your electrical needs.

Our Contacts:

Springtex Engineering Services Ltd

Mobile: 0721 692342, 0735 944253 or 0724 125211

Along Komarock Road, Mowlem Area, Off Kangundo Road, Nairobi

Email: [email protected]

Megger Resistance Test Circuit Testing HV Tests High performance insulation testers Electrical Testing Winding Resistance Meter HV test system testing insulation resistance Kenya Insulation Resistance Test High Voltage Testing

Read MoreInsulation and Winding Resistance Tests in Kenya

Sprintex Engineering Services Ltd are provider of Insulation Resistance Test and Winding Resistance Test Solutions in Kenya. We carry out Insulation Resistance Tests to ensure the healthiness of overall insulation system of electrical equipment such as detect the need for corrective, maintenance or replacement of installed equipment, assess if the newly installed equipment can be safely energized, as well as trend the gradual deterioration of the equipment over its service life. It reflects the presence or absence of harmful contamination, dirt, moisture and gross degradation.

We also offer Winding Resistance Test, also known as Contact Resistance Test to measure the resistance of electrical contacts of circuit breaker, isolators and bus bar. We us Winding Resistance Tests to verify that electrical connections are proper by detecting loose connections, eroded contact surfaces, contaminated or corroded contacts.

Our Contacts:

Springtex Engineering Services Ltd

Mobile: 0721 692342, 0735 944253 or 0724 125211

Along Komarock Road, Mowlem Area, Off Kangundo Road, Nairobi

Email: [email protected]

Insulation Resistance Test Winding Resistance Tests Electrical Equipment Insulation Contact Resistance Test Transformer Tester Contact Resistance Meter Circuit Breaker Timer Earth Tester LA Current Monitoring Battery Ground Fault Locator High Voltage Detector Kenya Nairobi

Read MoreElectric Motor Refurbishment and Reconditioning in Kenya

Springtex Engineering Services Ltd are specialist ELECTRIC MOTOR REFURBISHMENT and RECONDITIONING SERVICES providers in Kenya. We do electrical engineering repair services, comprehensive electric motor rewinding, complete motor refurbishment, motor repairs, repair of transformers, welding machines repair, synchronous motors repairs, electric generators repairs and rewinding of all electrical equipment to class H insulation systems.

All our electric machines repair work are subjected to thorough instrument and electrical tests that meet international standards before dispatch, as per international standards and quality test report provided on request.

We do Electric Motor Repairs on damaged or under performing AC or DC to get your motor up and running again. We repair everything electric; from alternators to niche brands of motor across a wide variety of sectors and industries. Whether your electric motor is experiencing underperformance or complete failure, our robust motor rewind, repair and refurbishment service will ensure that your motor performs like new again.

Other Electrical Motor Services we provide include:

Load testing

Armature testing

Motor core testing

Field testing

AC motor rewind

DC motor rewind

Varnishing stators and rotors

Undercutting and shimming commutator

Washing and stove windings

Shaft repair and replacement

Our Contacts:

Springtex Engineering Services Ltd

Mobile: 0721 692342, 0735 944253 or 0724 125211

Along Komarock Road, Mowlem Area, Off Kangundo Road, Nairobi

Email: [email protected]

electrical engineering repair services comprehensive electric motor rewinding complete motor refurbishment motor repairs repair of transformers welding machines repair synchronous motorsrepairs electric generators repairs class H insulation systems Electric Motor Repairs

Read MoreElectrical Motor Rewinders in Nairobi, Kenya

Sprintex Engineering Services Ltd is the leading electrical motor rewinding and electrical testing services expert in Nairobi, Kenya. We specialize in the widest range of electrical rewinding and testing services such as insulation and winding resistance tests, IR values, resistance, rotor eccentricity tests, vibration analysis and data collection using ADASH 4900 vibrio M analyser, mechanical motor measurements of the bearing journals or housings, electrical winding pulse, megger resistance and HV tests, electrical run, no load and load tests among many more.

We are specialist generator rewinders, transformer rewinders, transformer overhaul services providers, brake coils rewinders, clutch coil rewinders, refrigeration compressor rewinders, refrigeration overhaul services, pump motor rewinders, rotating equipment overhaul/service and brake coils rewinding.

Talk to the electric motor experts in Nairobi, Kenya. Get in touch with Sprintex Engineering Services Ltd.

Our Contacts:

Mobile: 0721 692342, 0735 944253 or 0724 125211.

Along Komarock Road, Mowlem Area, Off Kangundo Road

Email: [email protected]

winding resistance tests IR values rotor eccentricity tests motor measurements of the bearing journals megger resistance and HV tests electrical winding pulse generator rewinders transformer rewinders vibration analysis Kenya Nairobi

Read MorePump Motor Rewinders in Nairobi, Kenya

At Sprintex Engineering Services Ltd, we specialize in pump motor rewinding such as the repair, refurbishment and maintenance of borehole pumps, water boost pump motor rewinding, submersible sewerage pumps, swimming pool pumps and related equipment for water production, water transportation, wastewater collection and treatment for municipalities and industries in Nairobi, Kenya.

Our Pump motor rewinding and repair services include:

• Rewinding and rebuilding of pump motors

• water pump assembling

• Dismantle and clean and inspect parts

• Remove stator from casing

• Rewind pump stator

• Fit new cables, seals, bearings, float switches

• Tank testing

• Pump painting

We are always striving to be cost effective, customer driven, fast and flexible and are continuously improving on the quality of our services.

Our Contacts:

Mobile: 0721 692342, 0735 944253 or 0724 125211.

Along Komarock Road, Mowlem Area, Off Kangundo Road

Email: [email protected]

pump motor rewinding pump motor repair pump motor overhaul borehole pump motor experts swimming pool pump motor rewinders submersible pump motor rewinders Kenya Nairobi Water Boost Pump Motor Winding

Read More